TEANKA Products

Plastic Pipe Lines

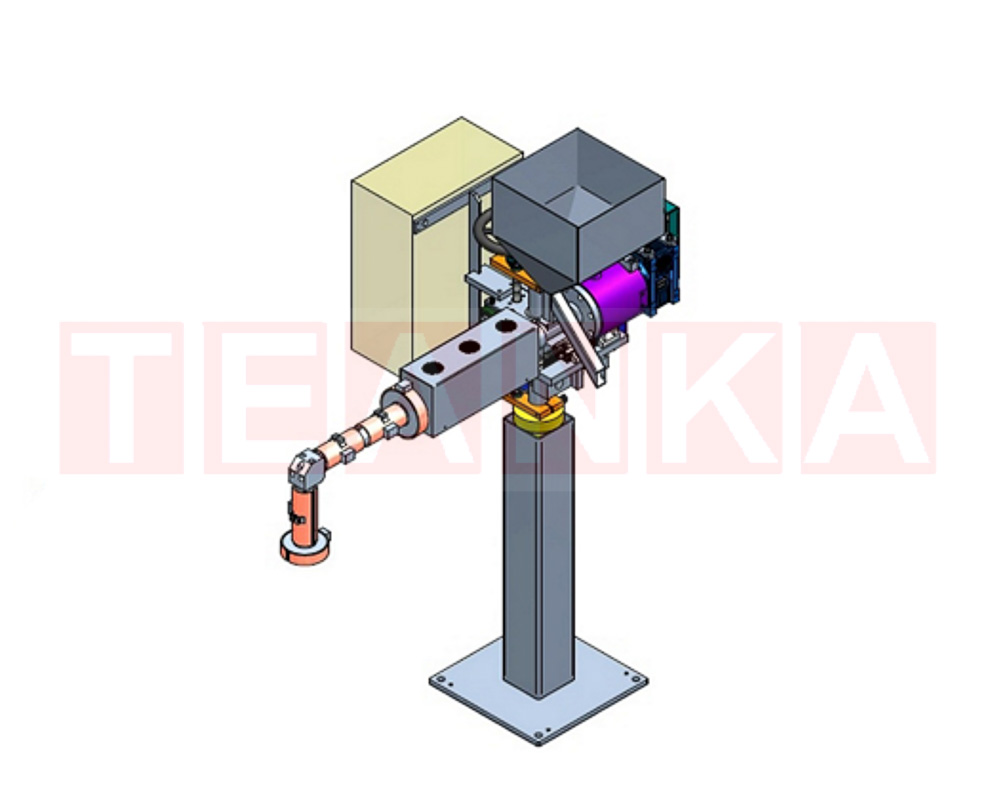

Co-Εxtruders

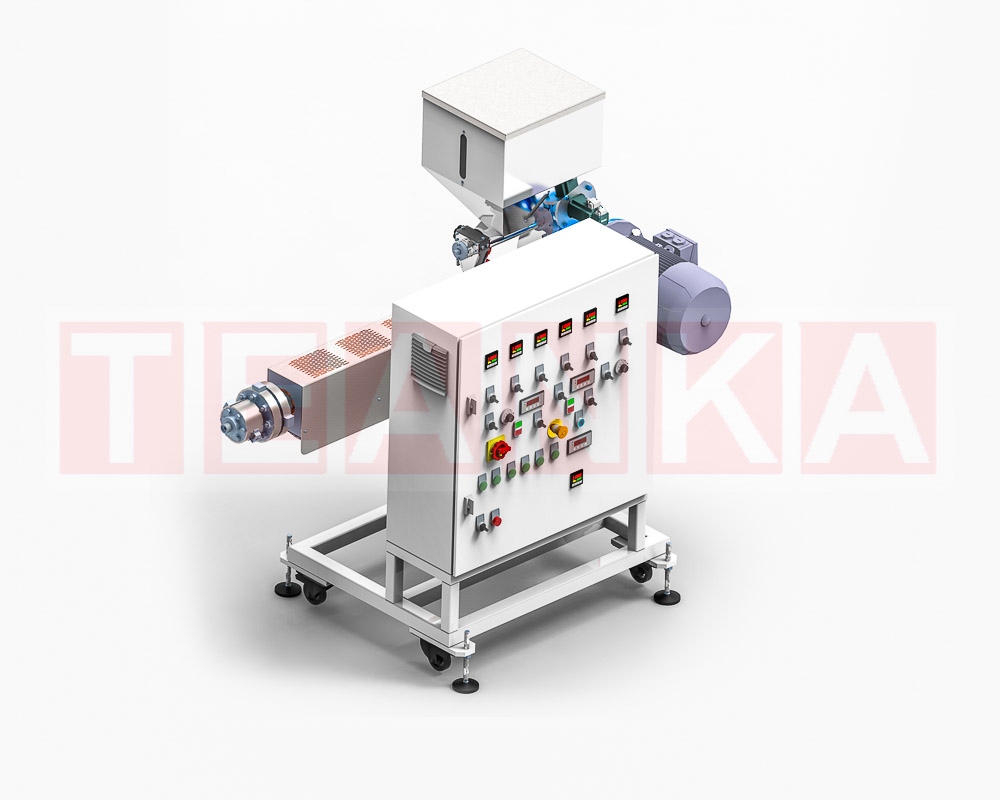

TEANKA manufactures co-extruders from diameters Φ22 to Φ45.

All lamination units (screw - cannon) are made in collaboration with an Italian company which has long experience in their construction. They have been nitrified, ie surface treatment (staying in a nitrogen atmosphere for several hours) to increase the strength of the material.

Considering how important is the production stability and reliability in continuous operation, we use the most reliable inverter / converter systems with encoder close loop controls, and branded motors - reducers of the European market.

Co-Extruders for Limited Spaces

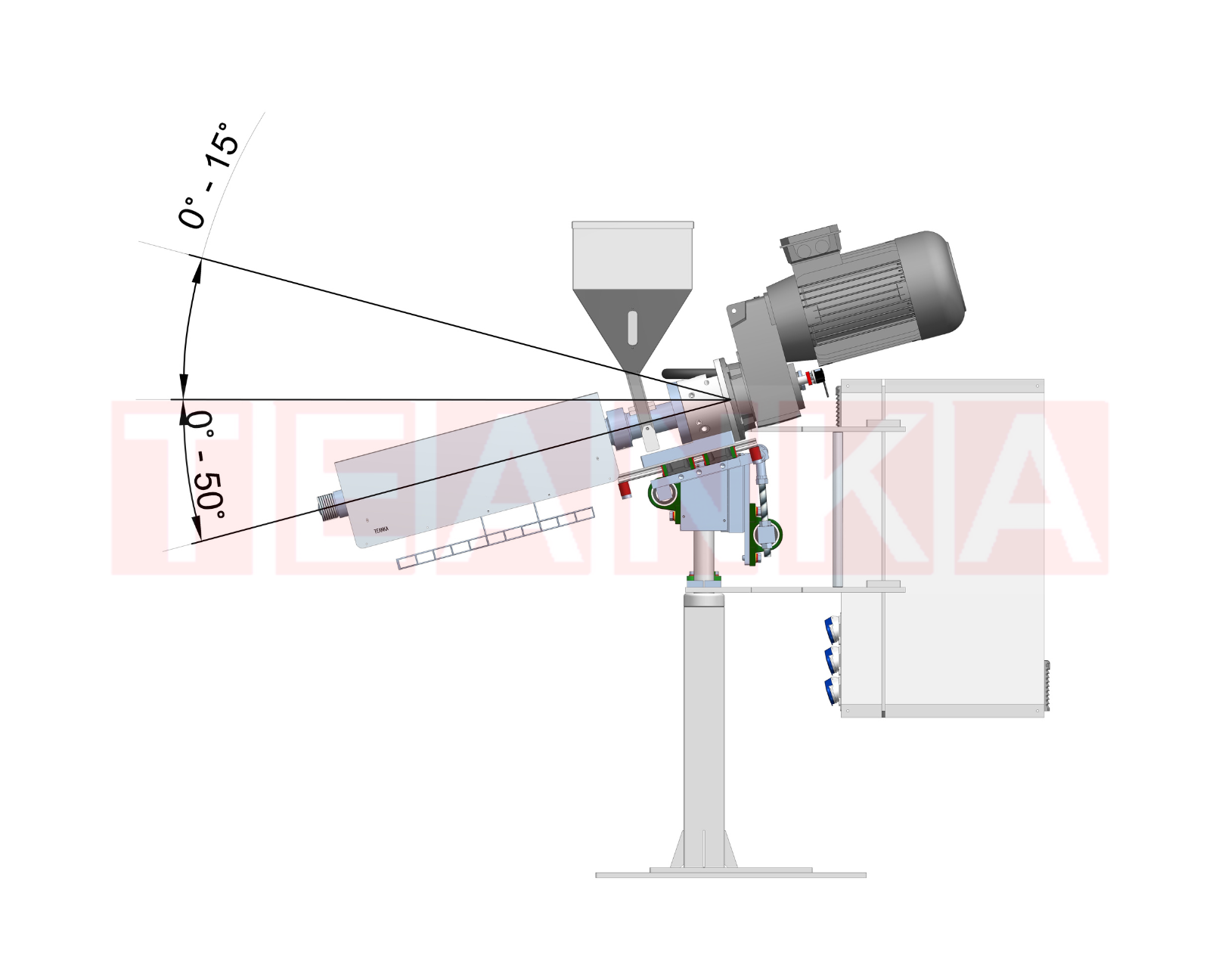

TEANKA co-extruders are designed to be able to operate in limited spaces that usually exist next to main extruders and for this reason, they can have:

- Height adjustment

- Tilt adjustment

- Linear motion (approach - removal from the head)

- Axis rotation

- Flexible or stable connection to the head

- Fixed or wheeled base

- Base for mounting 2 co-extruders

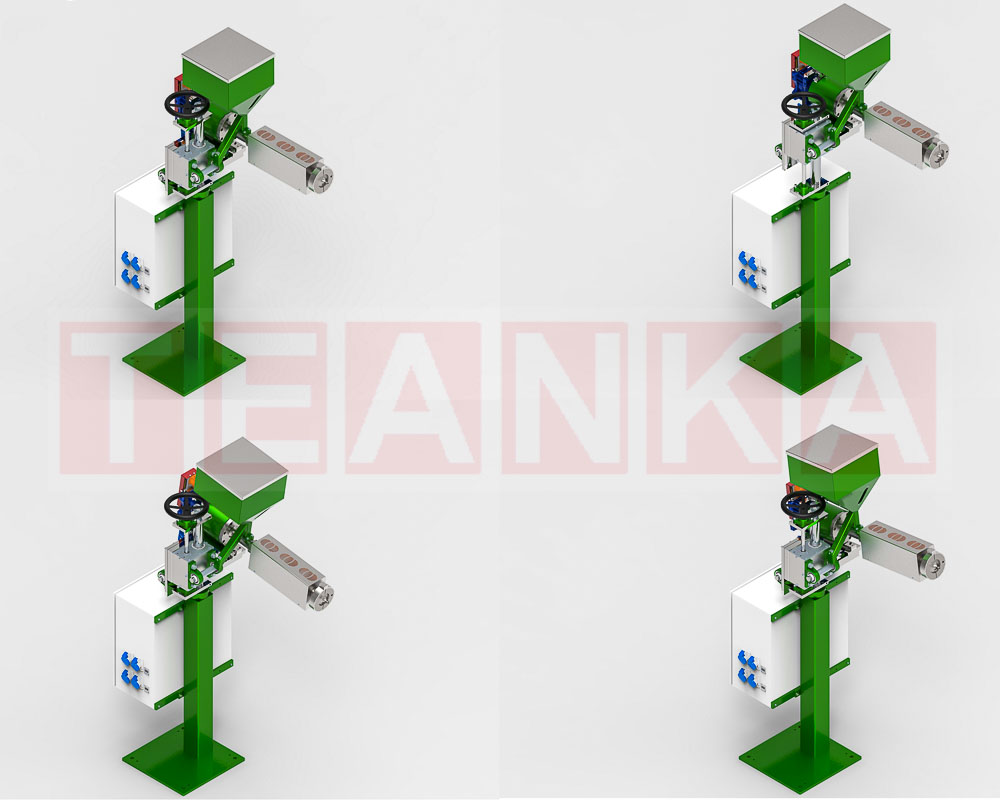

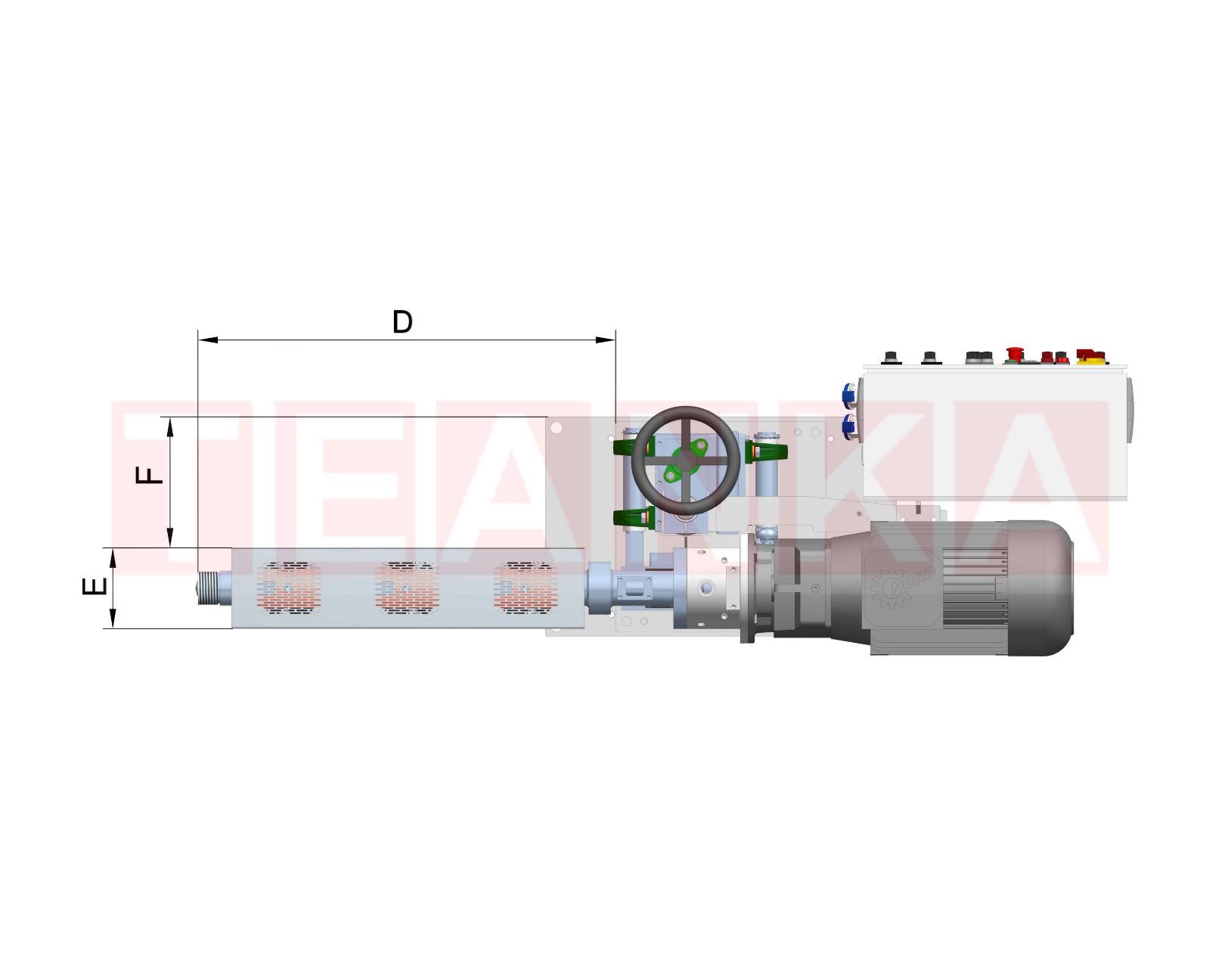

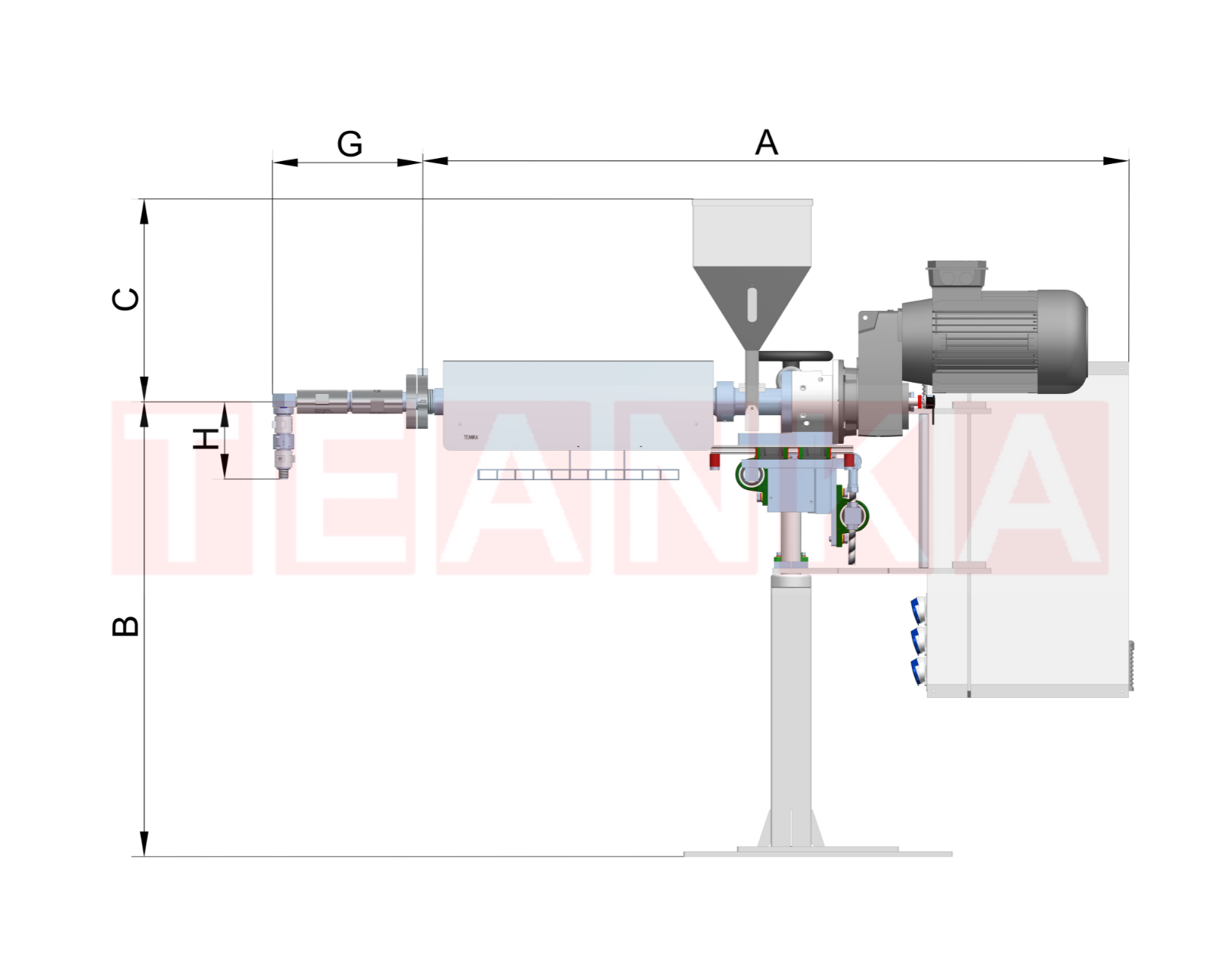

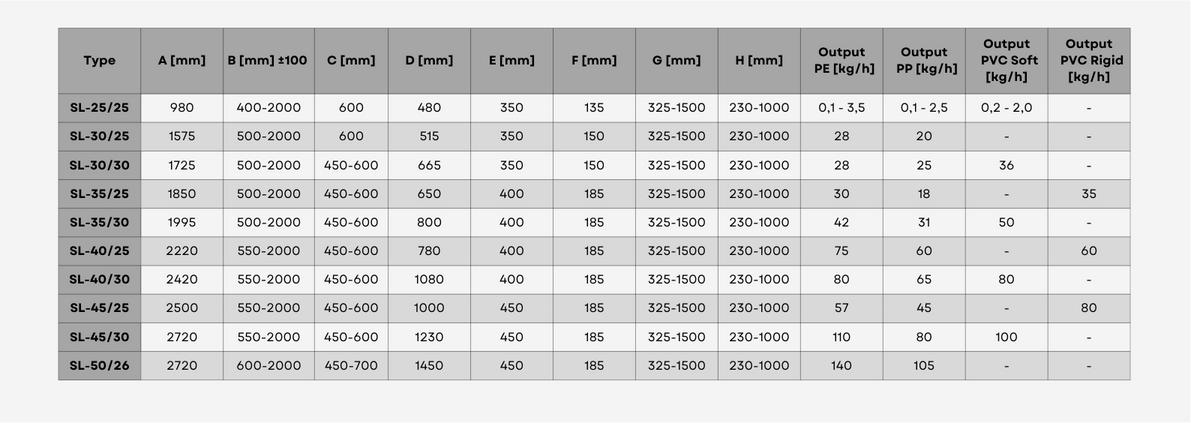

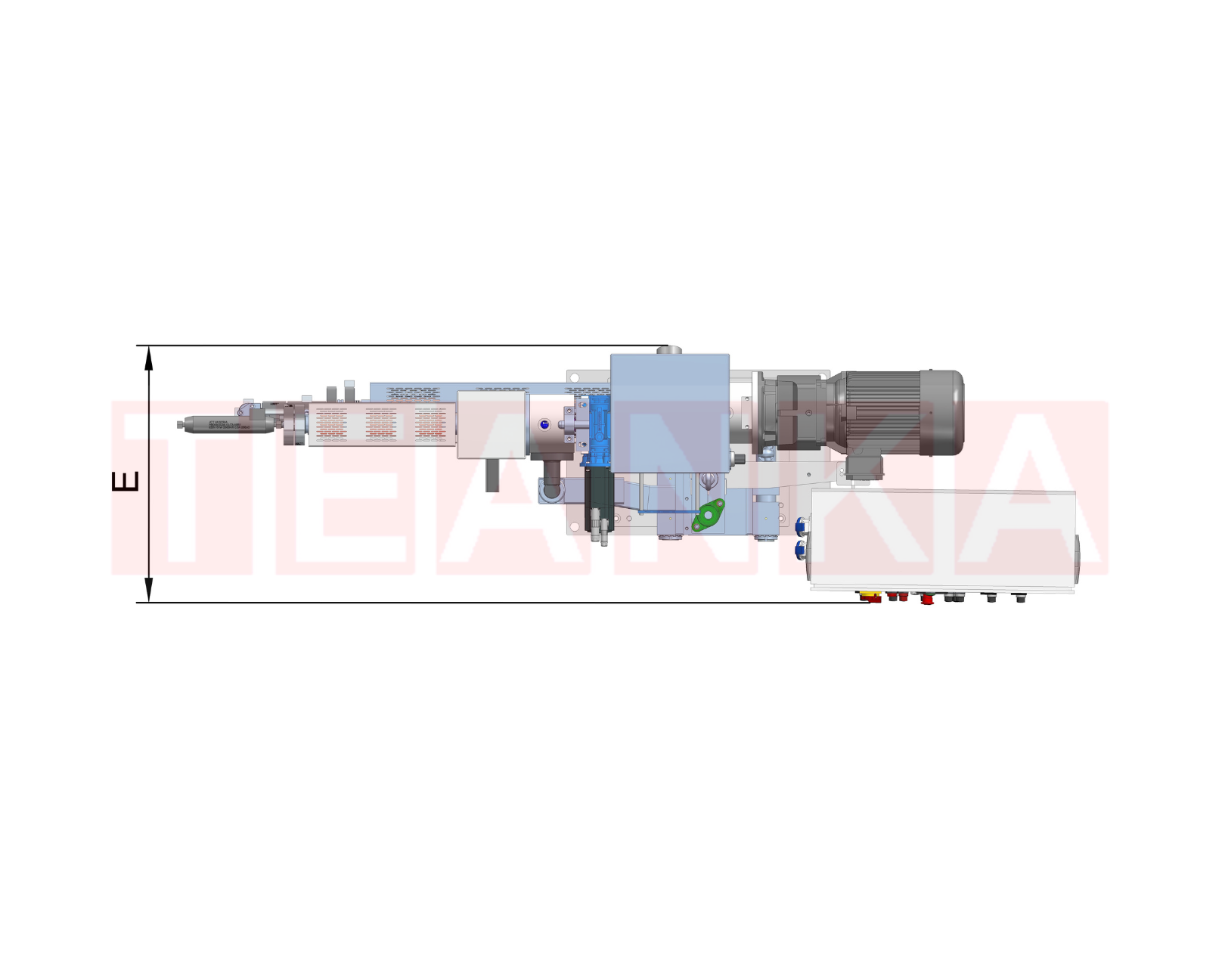

SL Co-Extruders For Limited Spaces

Slim-sized Co-Extruder that can fit more than one in a head. Especially designed to operate at high pressures (550 – 700 bar).

TEANKA co-extruders are designed to operate in limited spaces that usually exist next to main extruders.

- Barrel – Nitrated and grooved.

- Barrier screw – Nitrated.

- AC motor with frequency converter and encoder feedback.

- 3 – 4 heating zones at barrel with J type thermocouples.

- 3 – 4 cooling fans at the barrel.

- Ιnfrastructure for 3 – 4 heating zones for adaptor, flexible hose and nozzle, with J type thermocouples.

- Water cooling with valve at the thrust bearing area.

- Water cooling at the feeding zone with valve.

- Co-extruders on linear bearing, with ability to be connected with head without tension.

- Sturdy and powerful design.

- Low energy consumption.

- Up – down movement.

- Rotational movement on the vertical axis.

- Rotational movement on the horizontal axis.

- Back and forth movement on a linear bearing.

- Fast delivery.

- Color choose option.

- User manual and interface in English language.

Ideal for multilayer heads mainly for tube and profile production. Optional: PLC and touch screen drive capability (for one or more co-extruders) - Compatible Industry 4.0

Press to zoom in

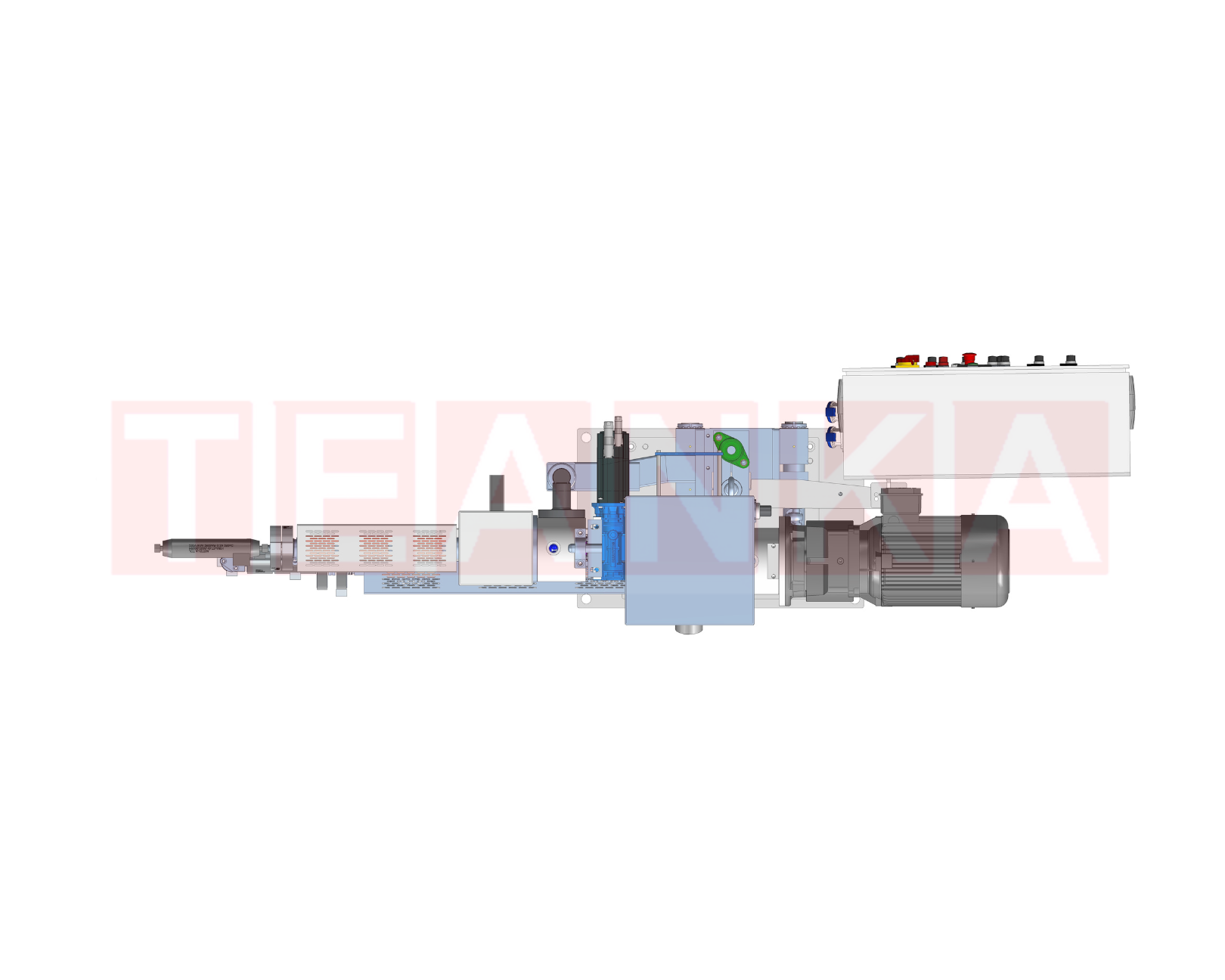

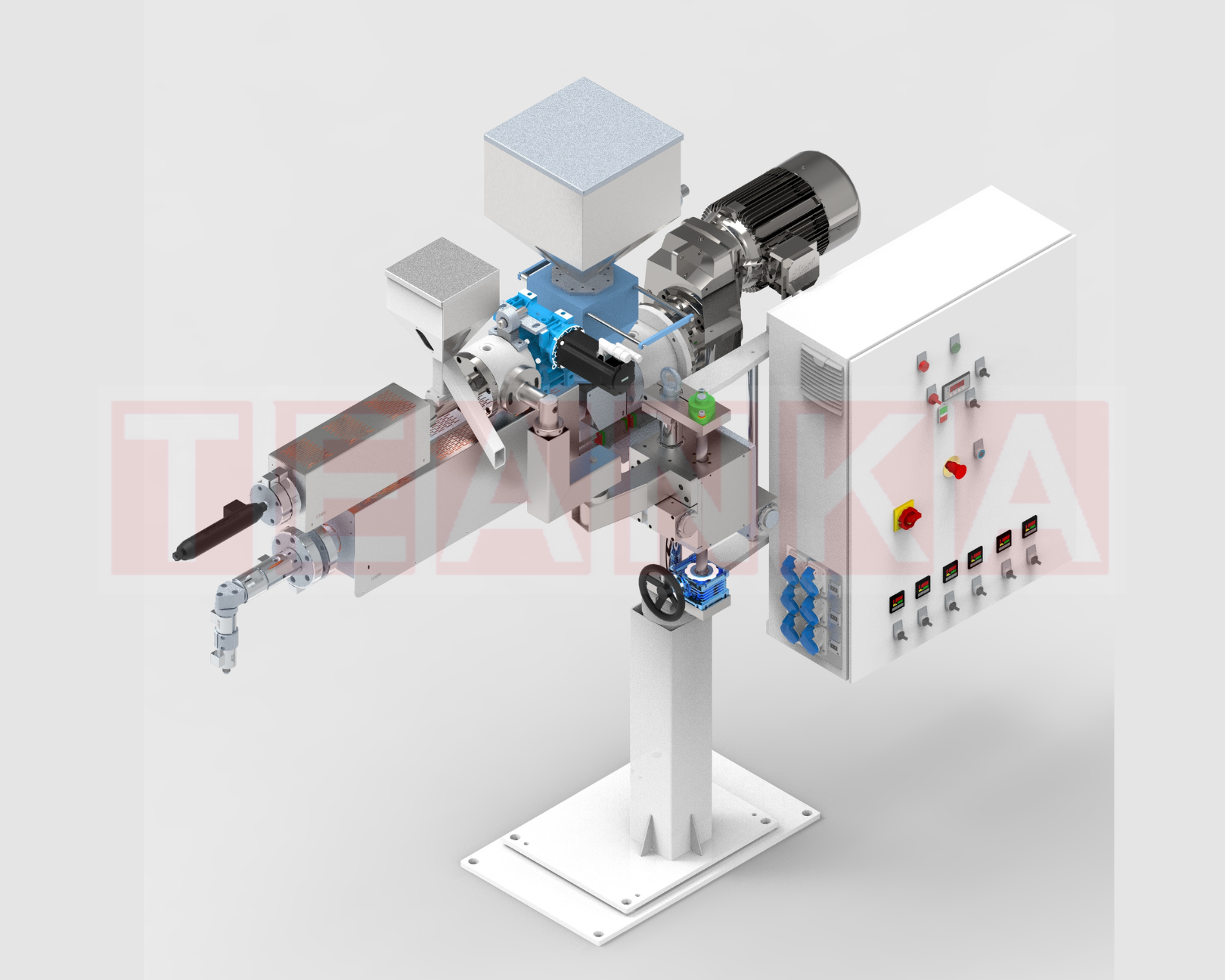

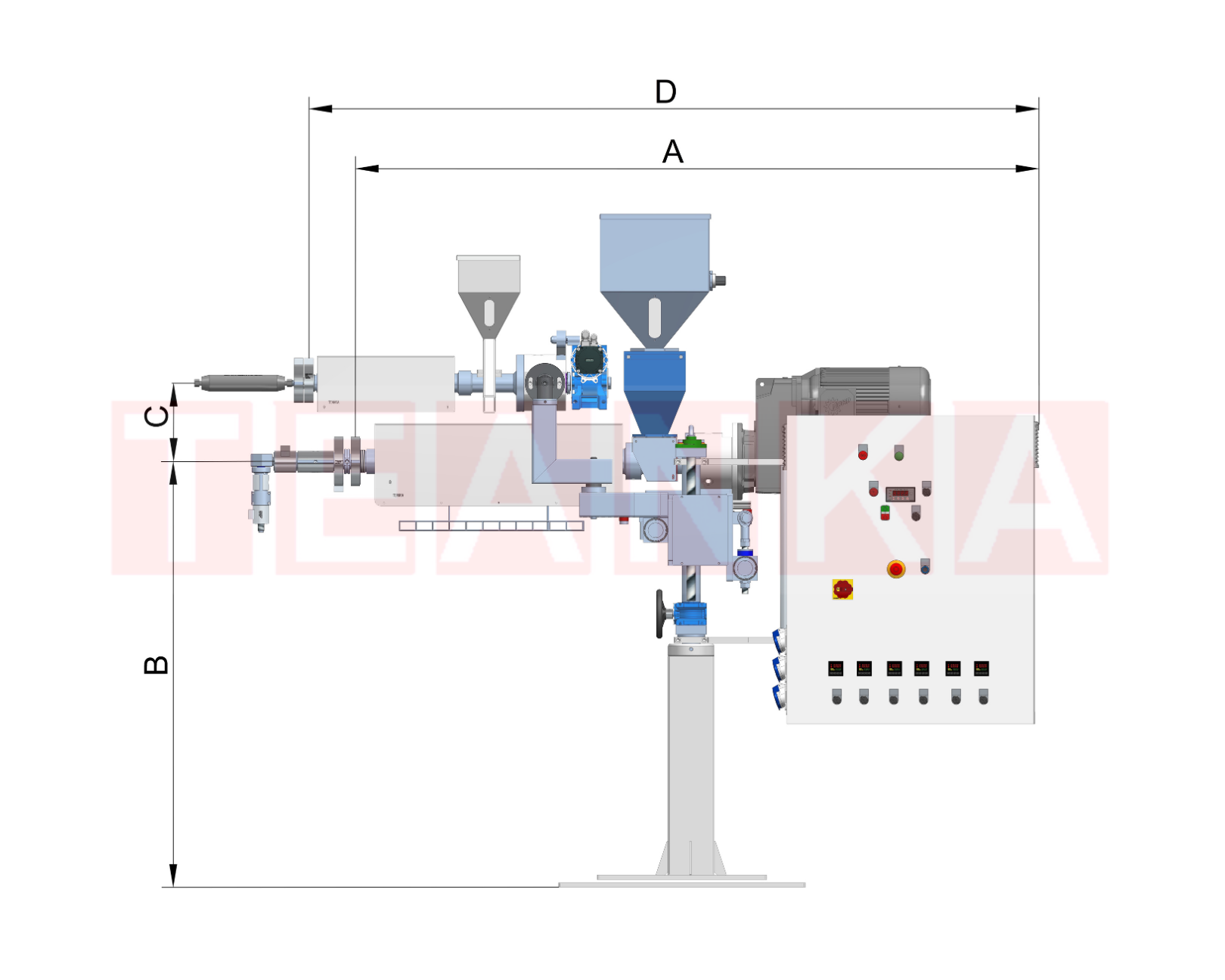

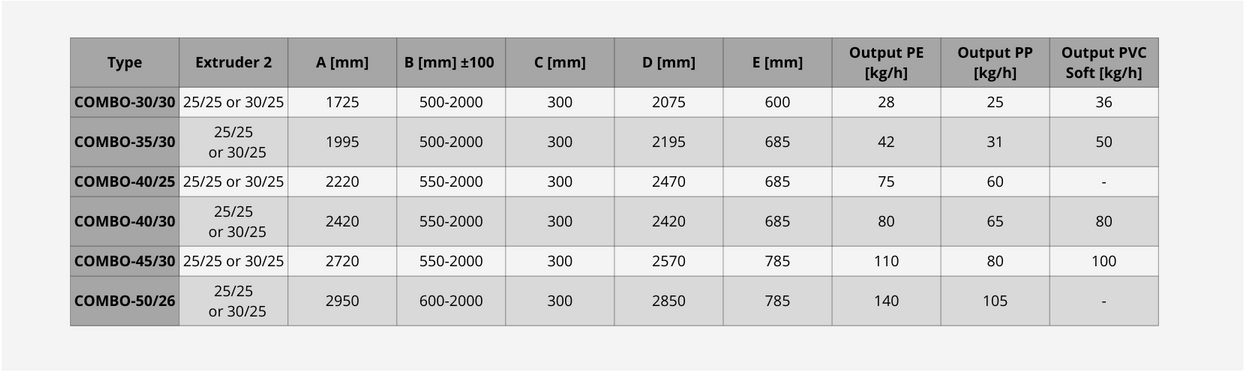

COMBO Co-Extruders For Multi Layer Pipes

COMBO Co-Extruders are especially designed to fit two extruders in one single space.

Standard solution for very limited spaces. Same capabilities and functions as SLIM CO-EXTRUDERS. Considering how important is the production stability and reliability in continuous operation, we use the most reliable inverter / converter systems with encoder close loop controls and branded motors - reducers of the European market.

Press to zoom in

More Co-Extruders

Press to zoom in

Available Downloads

Press to download this