TEANKA Products

Plastic Pipe Lines

Winding Stations

TEANKA has more than 40 years of experience in design and manufacture of winding stations and systems.

Our Winding Systems are:

- For pipes from Ø 3mm to Ø 125mm.

- Semi-automatic or Automatic. Single or Double.

- For coils with internal diameter from Ø 100mm to Ø 4000mm.

- Winding length up to 7000m.

- For winding speeds up to 350 m/min.

- For coils weight up to 2000 kg.

TEANKA manufactures a wide variety of winding stations even for very small pipe diameter pipe (Φ3) and in various winding diameters (up to Φ3500 outer diameter)

Technical Specifications:

- One or two winding stations

- Arrangement of stations in a row or right-left

- Automatic or semi-automatic winding and roll change function

- Winding on a fixed spool or without a spool

- A mechanism moves the insert pipe right - left, across the width of the spool so it can built correctly

- Cutting by measuring tube length at the spool or by command from the central production line control or the printer

- Binding system with hoop

- Wheels for easy movement inside the production area

- Large roll width for rolls of many meters

- Special corridor - guide for passing the hoop by hand, in wide buns

- Holding the end of the tube after cutting so the spool does not unwind

- Possibility in the same winder to change the internal curvature, for a better result in thin tubes and in different diameters

- Special design of feather plates, not to damage the pipe

- Grip the beginning of the pipe at the start of the winding

- Change the inner diameter automatically with electric drive for big winders

- Possibility of transfer even the biggest winders with common trucks or containers (diameter of stations over 3m)

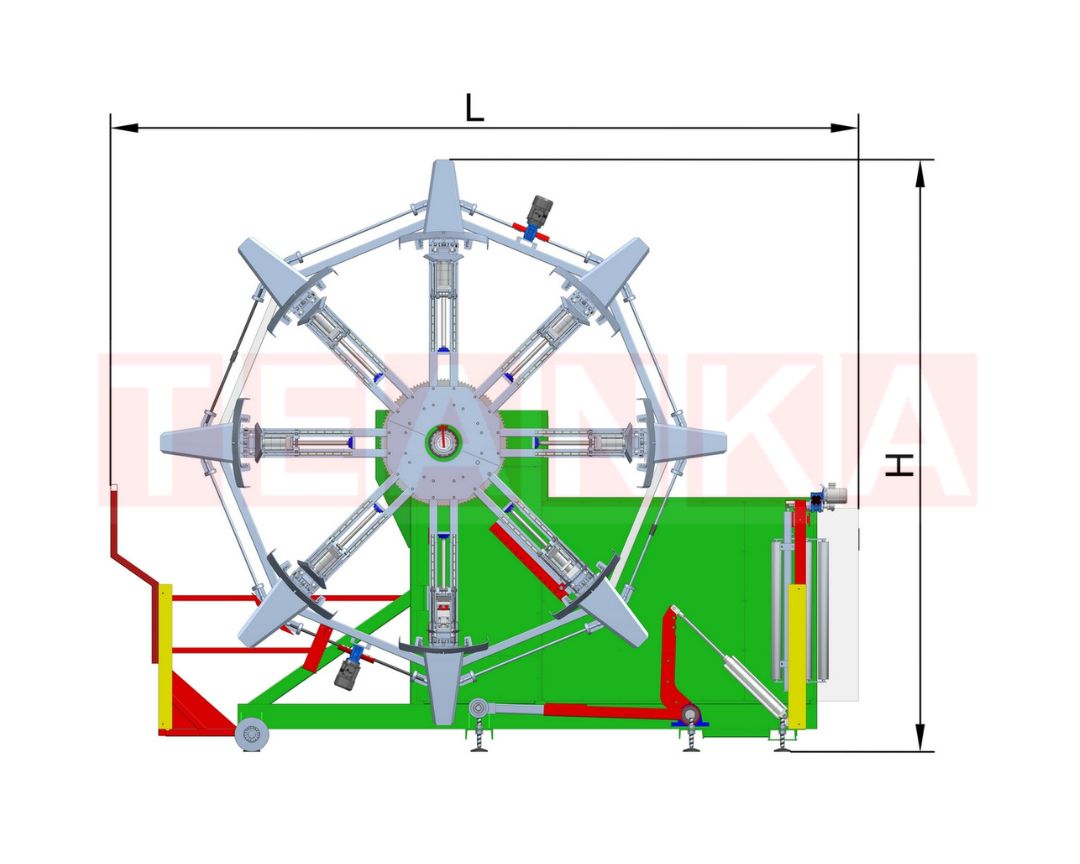

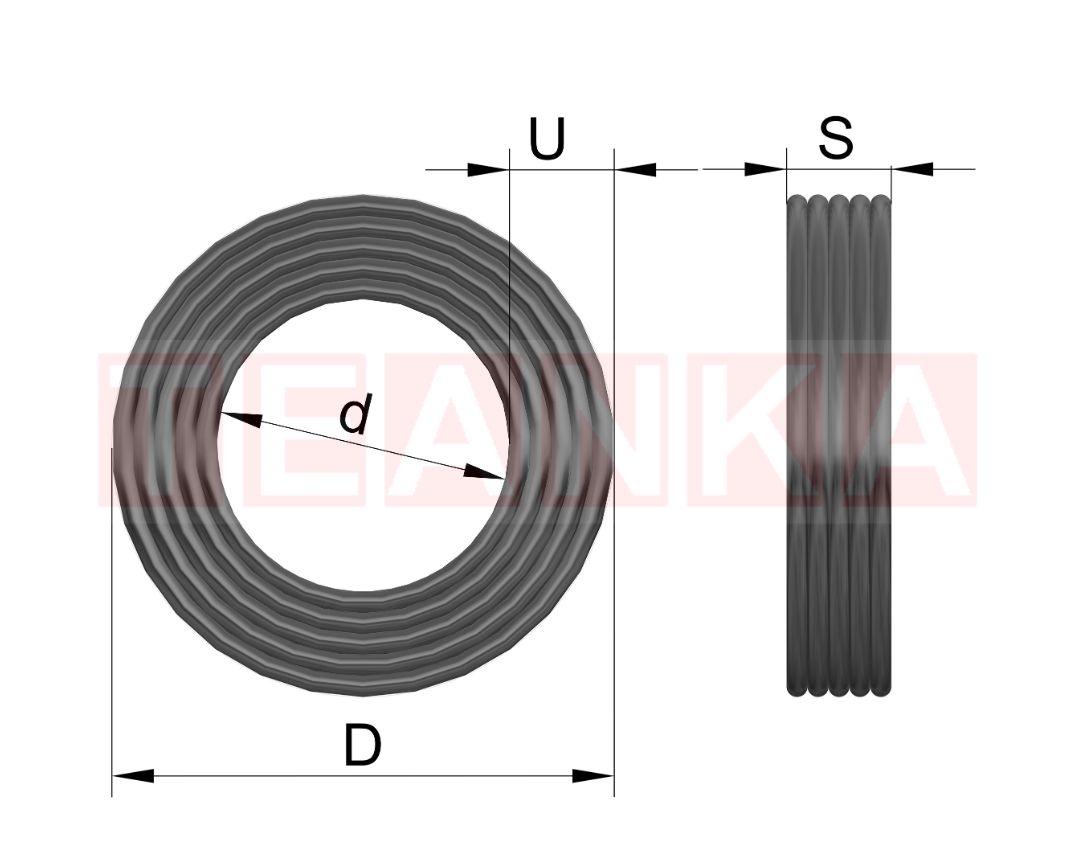

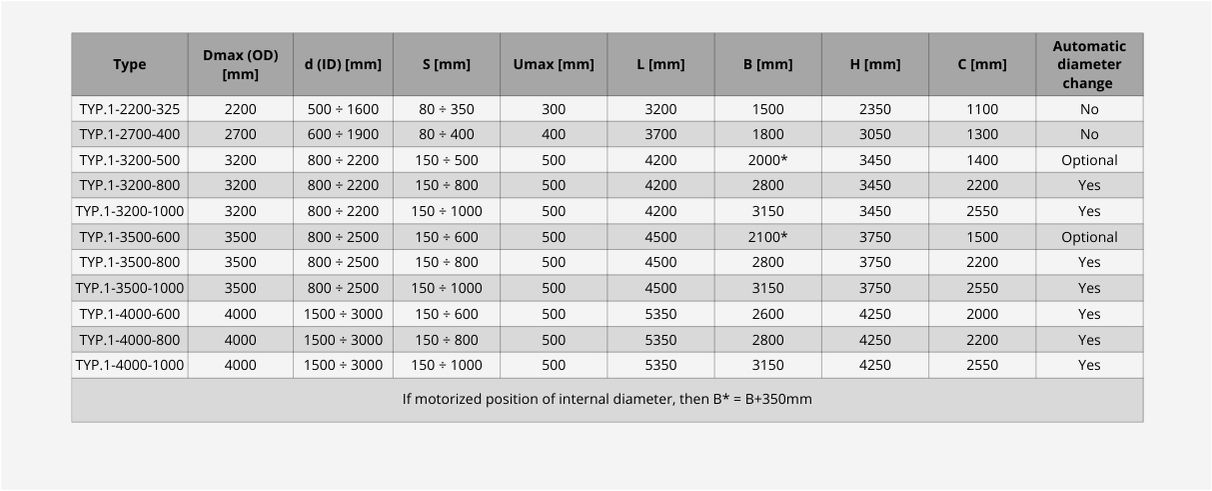

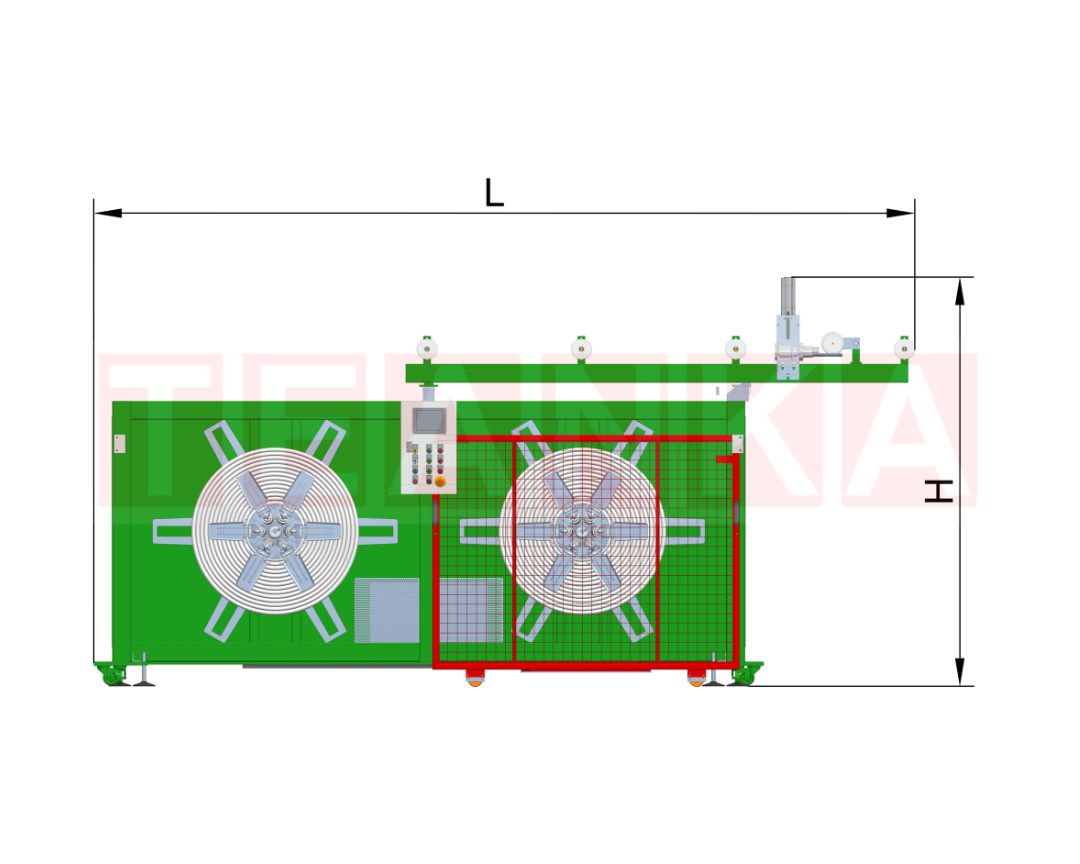

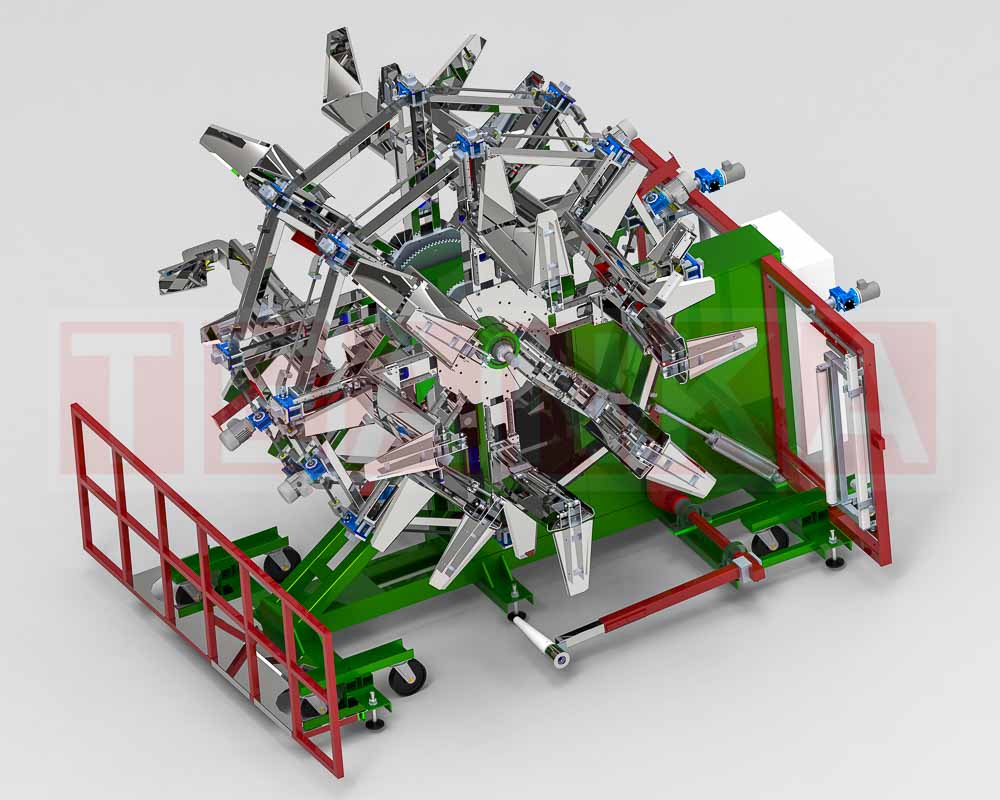

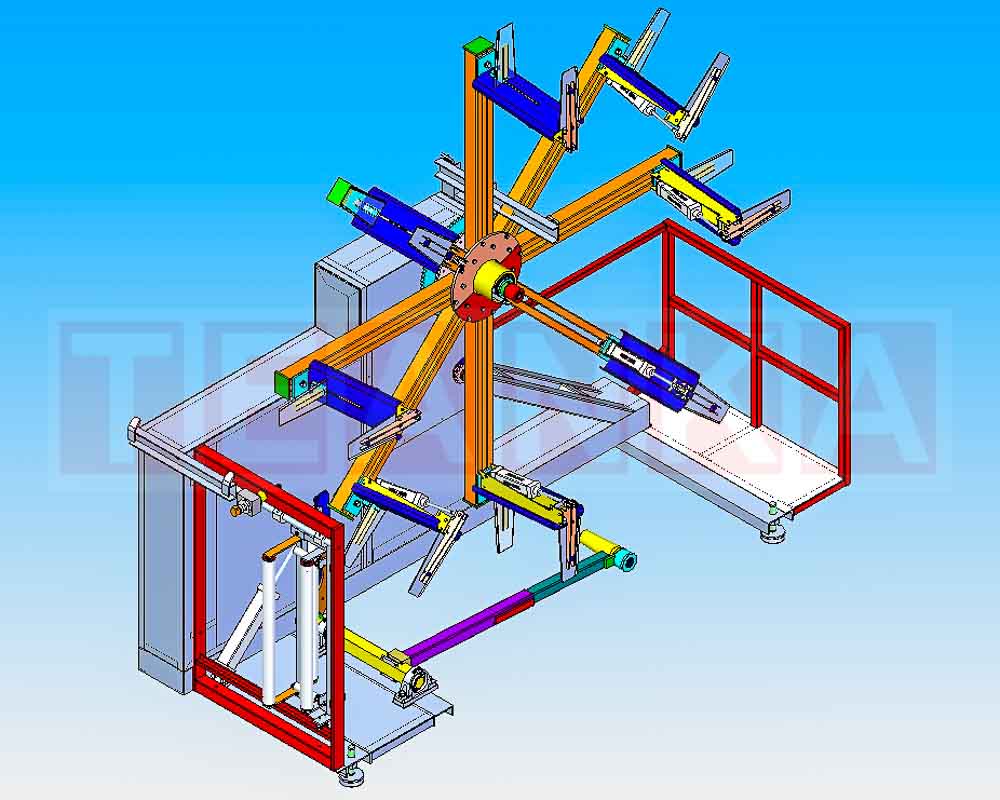

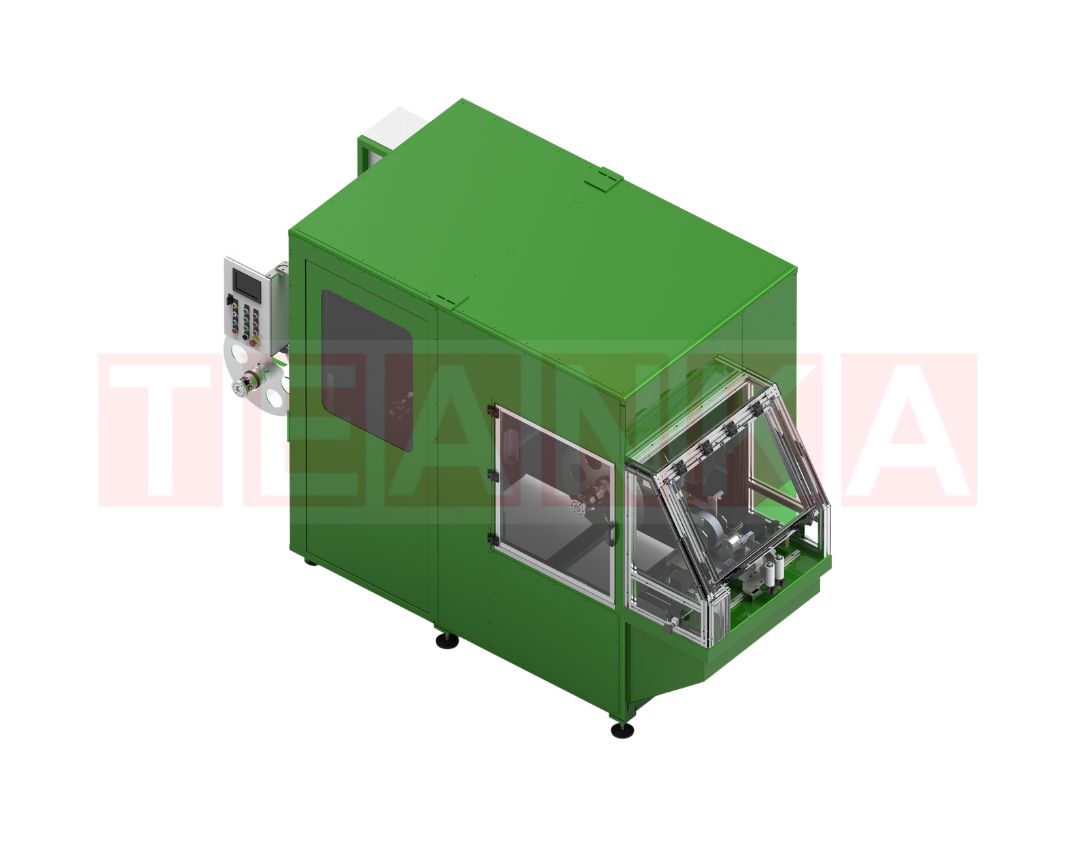

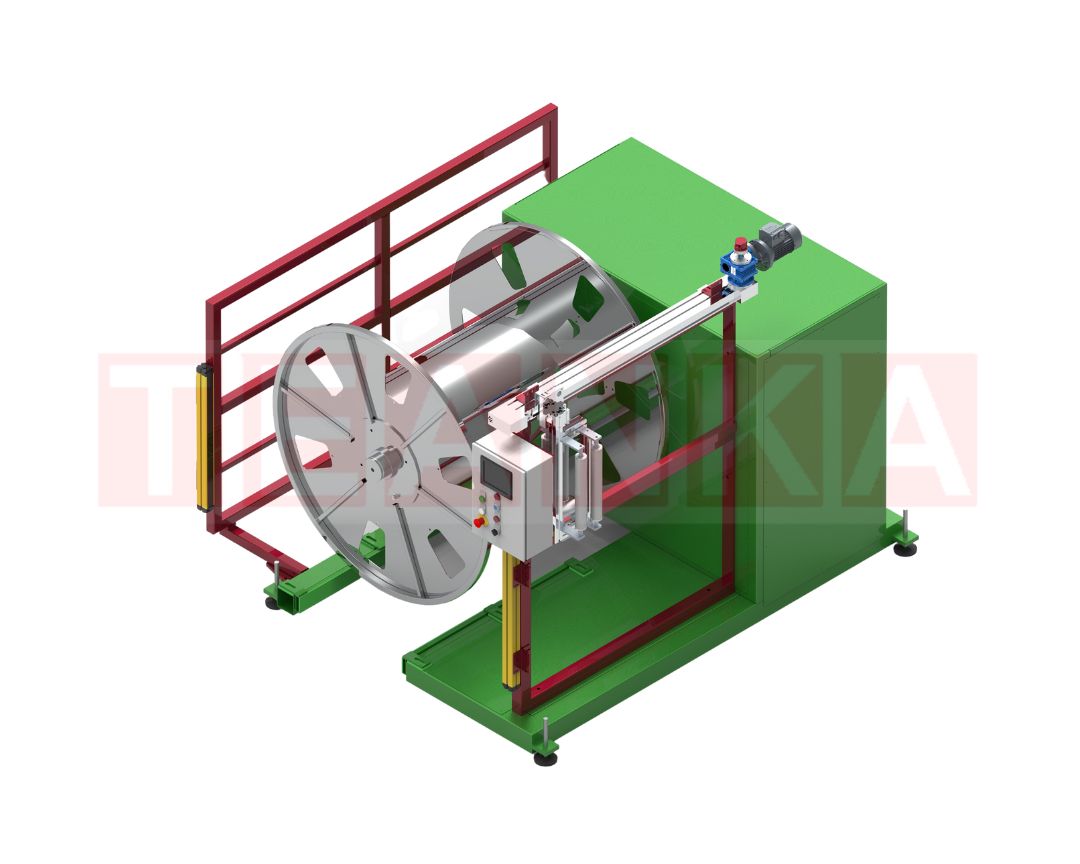

TYP-1-2200/4000 | Large Single Winding Stations

TYP-1-2200/4000 series are large double winding stations, with a winding diameter of up to 4000mm. They are ideal for installation in limited spaces, due to their special design with the minimum possible width.

Features

- One (1) winding station.

- 7” Touch Screen and Siemens PLC, with Industry 4.0 standards.

- Large coil width for long rolls.

- Holding arm for optimal winding quality and easy tying by the operator.

- Ability to communicate with the cutting machine to carry out stopping procedures.

- Capable of transportation with common trucks or containers.

Optional equipment

- Holding the pipe’s edge when starting the winding.

- Changing of the internal diameter automatically with electric drive.

- Shrinking the navel wrap for easy extraction of the coil.

- Inserted wings to change the winding curvature for better results in thin pipes and in different diameters.

- Wheels for easy movement within the production area.

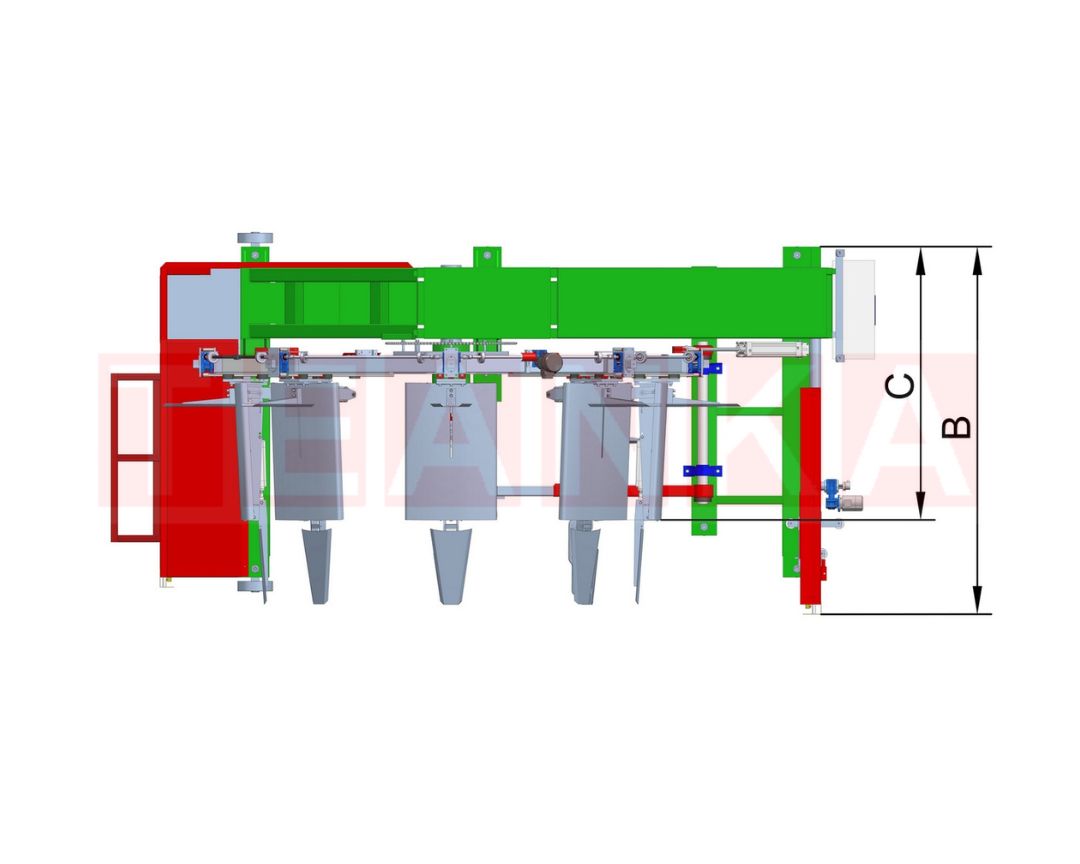

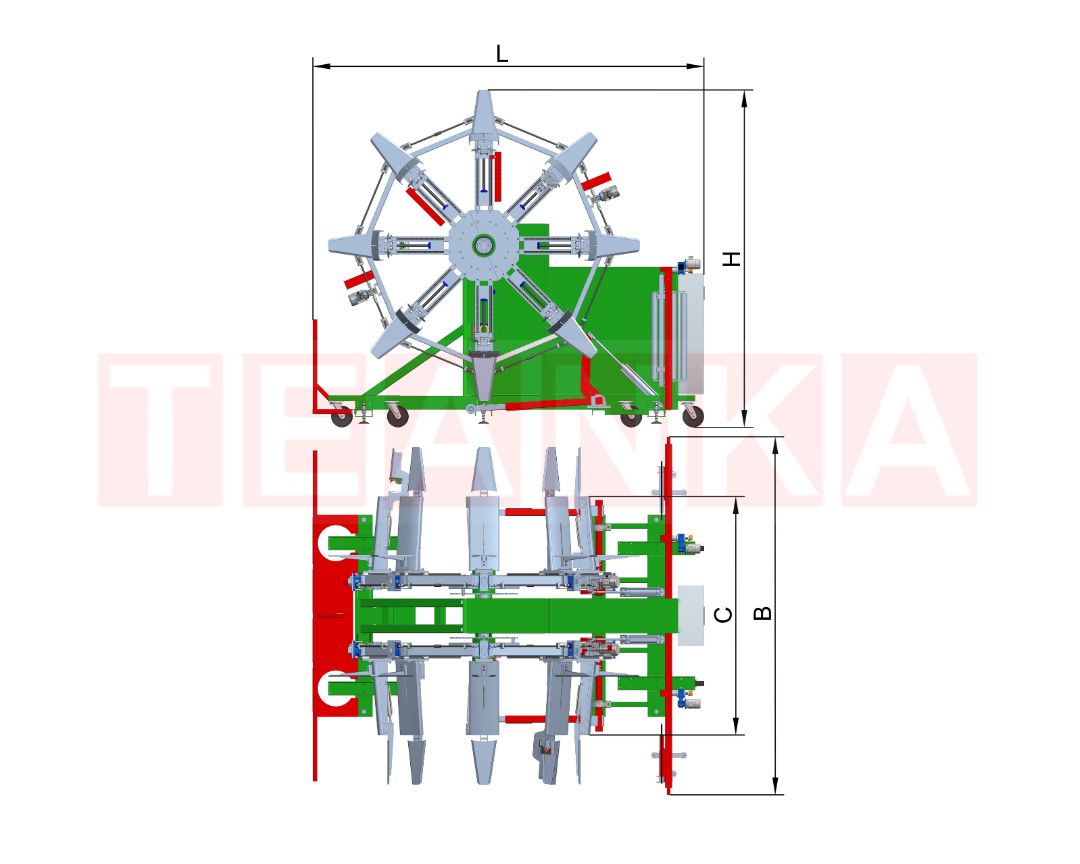

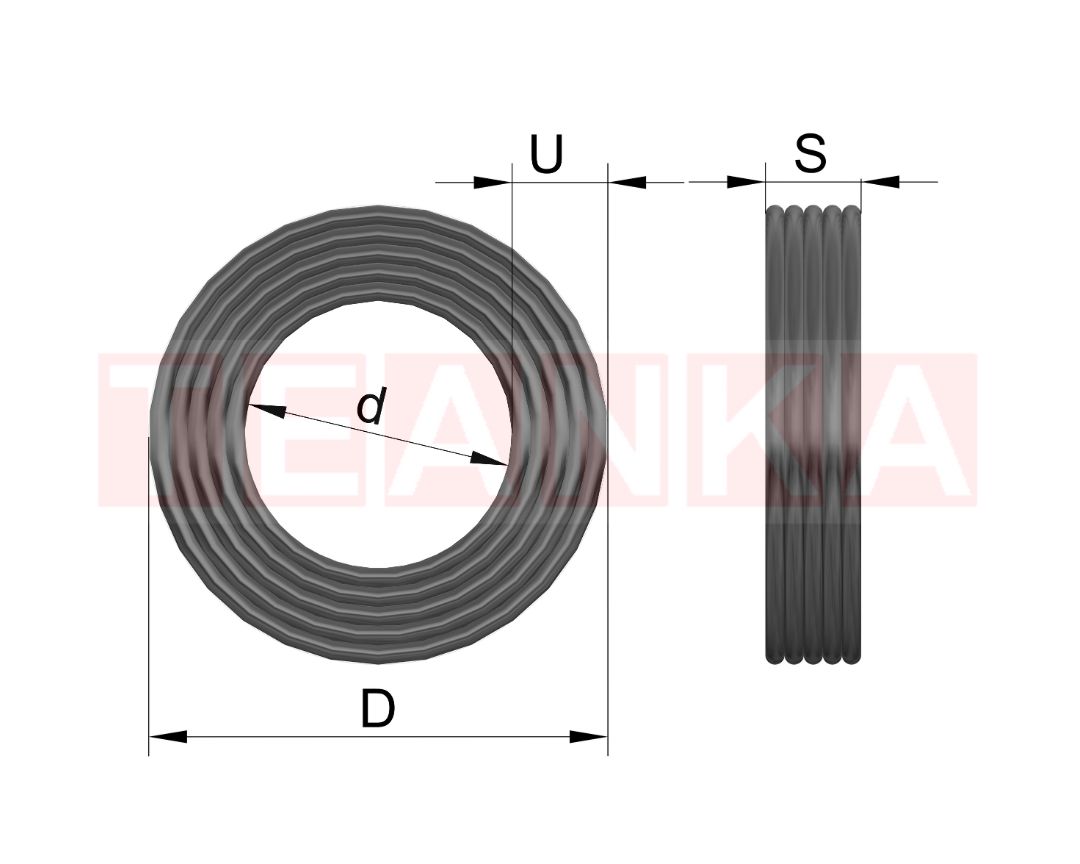

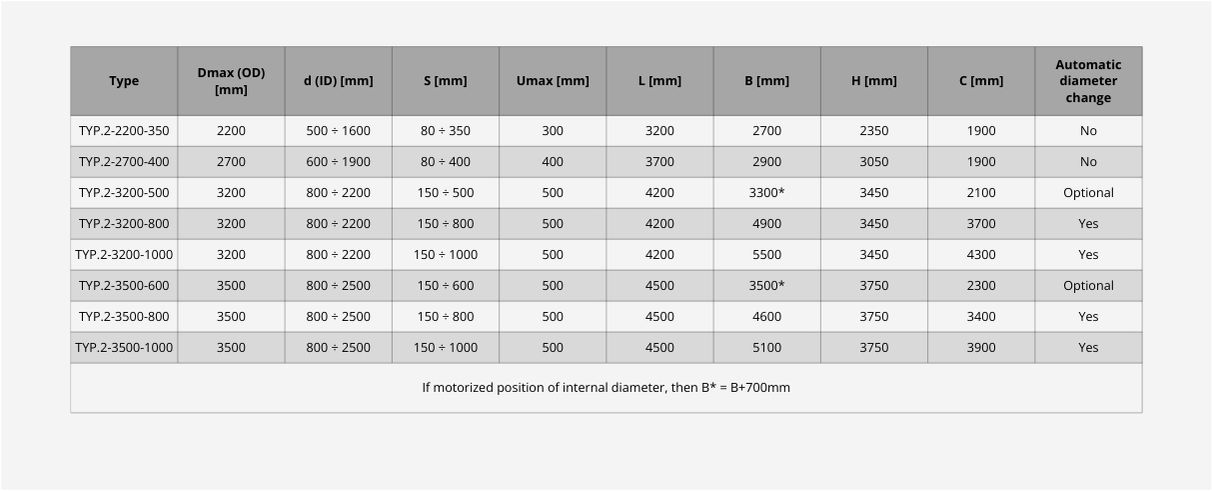

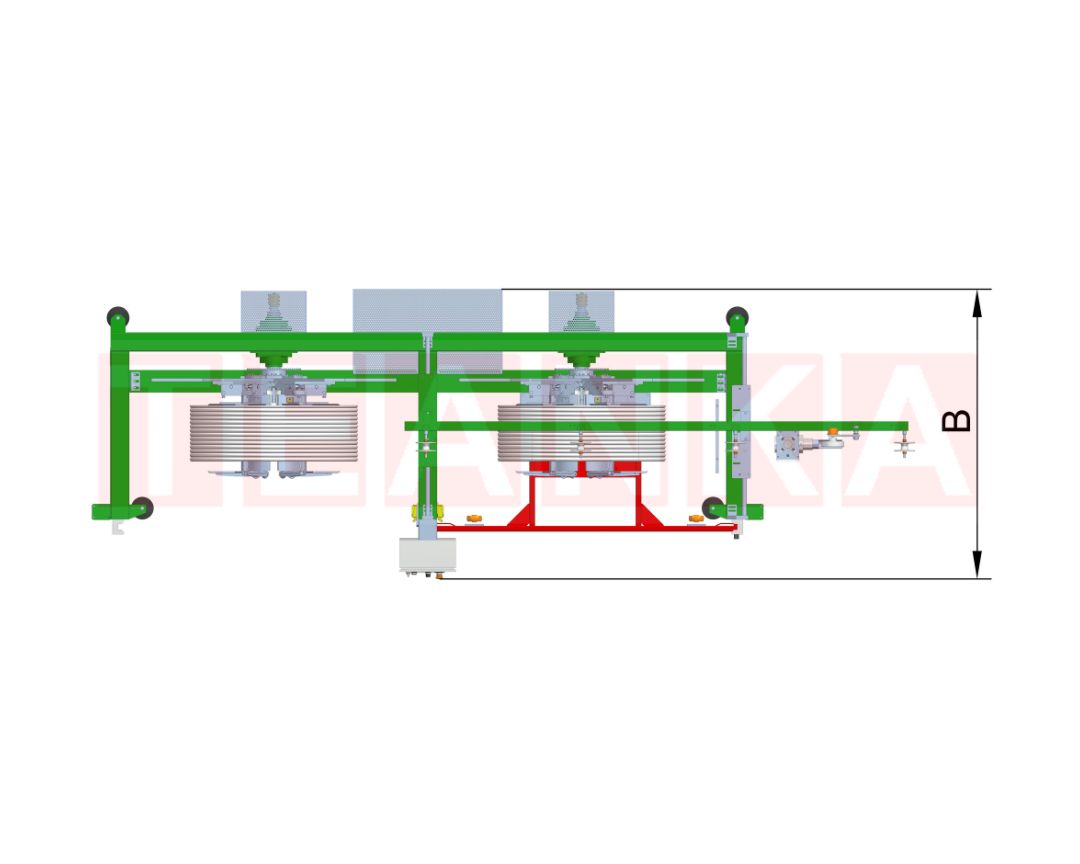

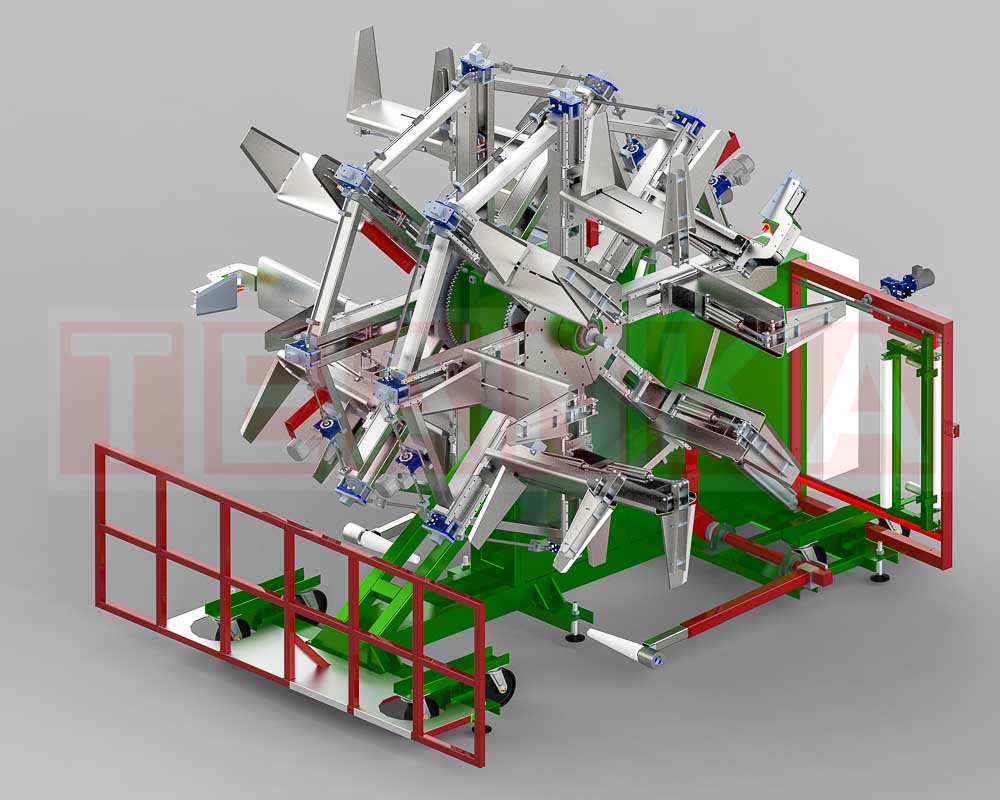

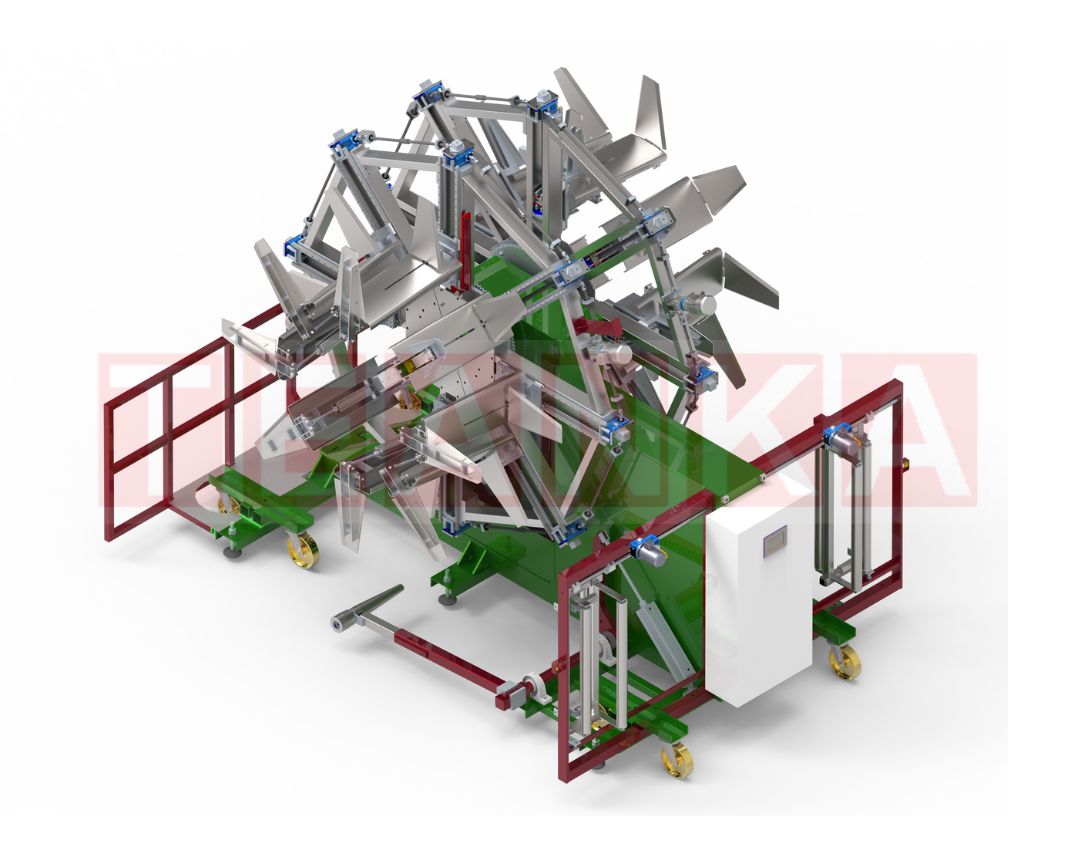

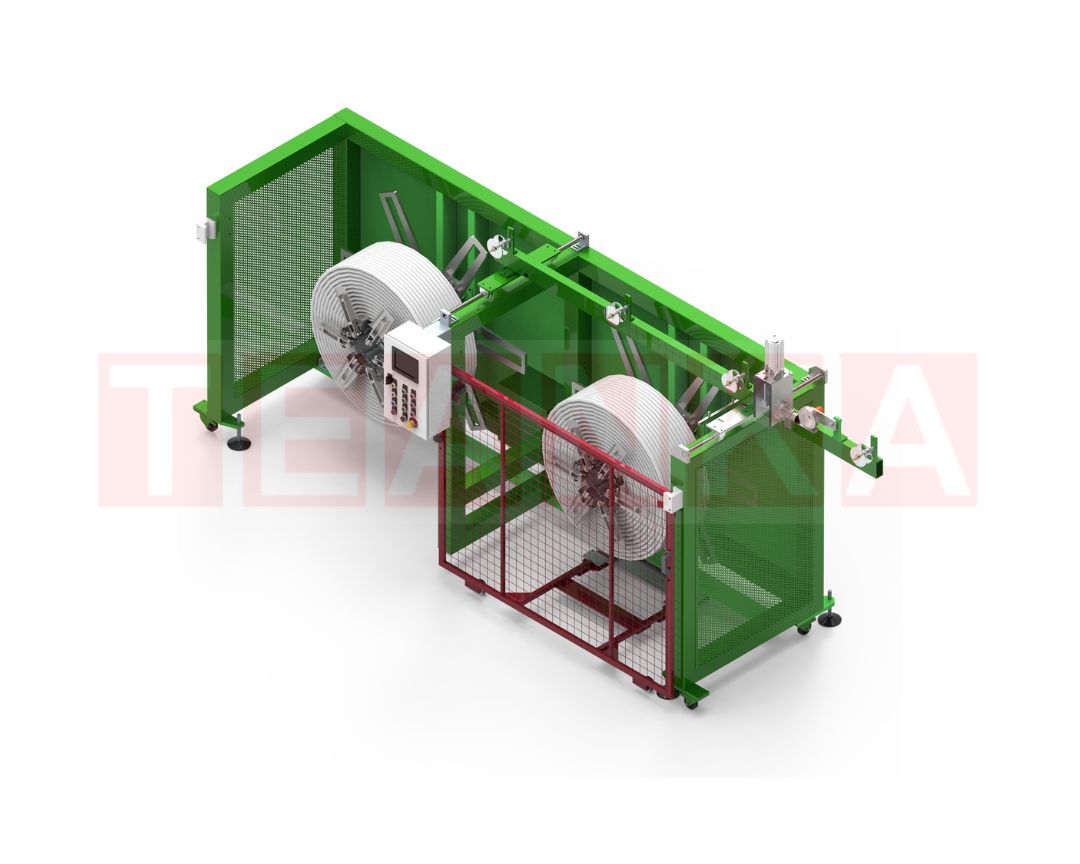

TYP-2-2200/3500 | Large Double Winding Stations

TYP-2-2200/3500 series are large double winding stations, with a winding diameter of up to 3500mm. They are ideal for installation in limited spaces, due to their special design with the minimum possible width.

Features

- Two (2) winding stations.

- 7” Touch Screen and Siemens PLC, with Industry 4.0 standards.

- Large coil width for long rolls.

- Holding arm for optimal winding quality and easy tying by the operator.

- Ability to communicate with the cutting machine to carry out stopping procedures.

- Ability of simultaneous operation of both stations, winding 2 different tubes.

- Capable of transportation with common trucks or containers.

Optional equipment

- Holding the pipe’s edge when starting the winding.

- Changing of the internal diameter automatically with electric drive.

- Shrinking the navel wrap for easy extraction of the coil.

- Inserted wings to change the winding curvature for better results in thin pipes and in different diameters.

- Wheels for easy movement within the production area.

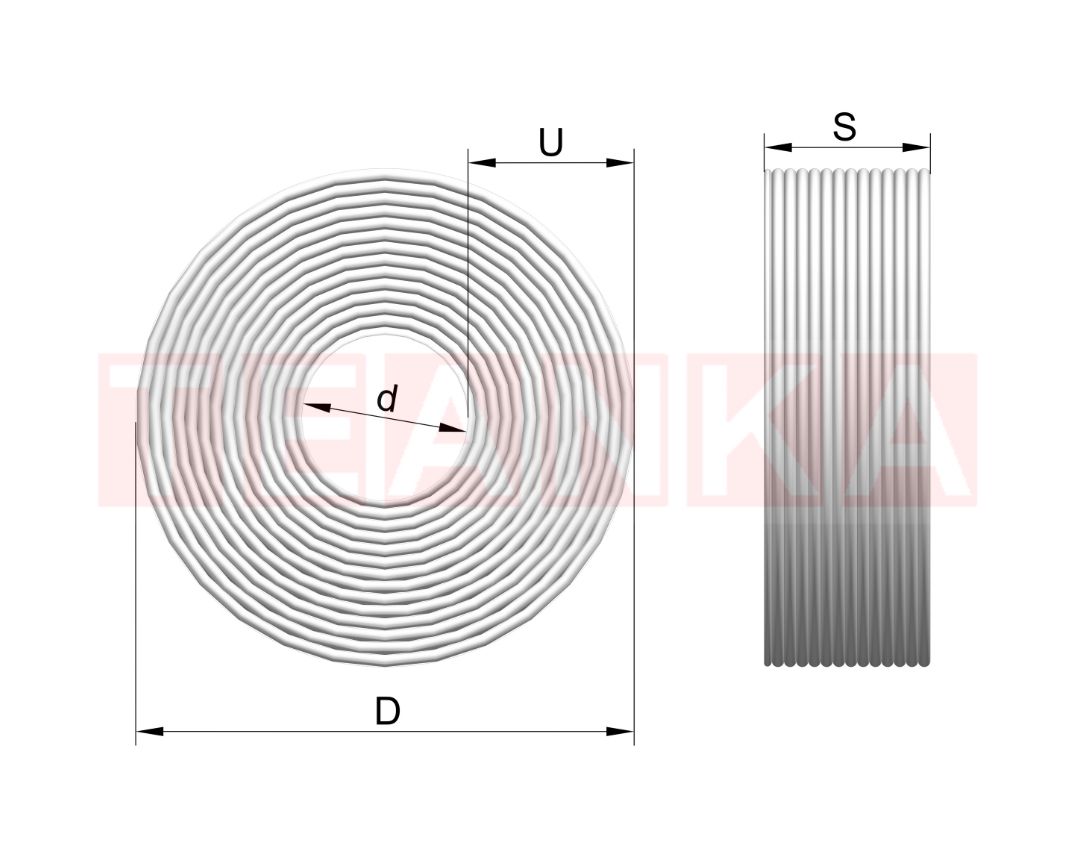

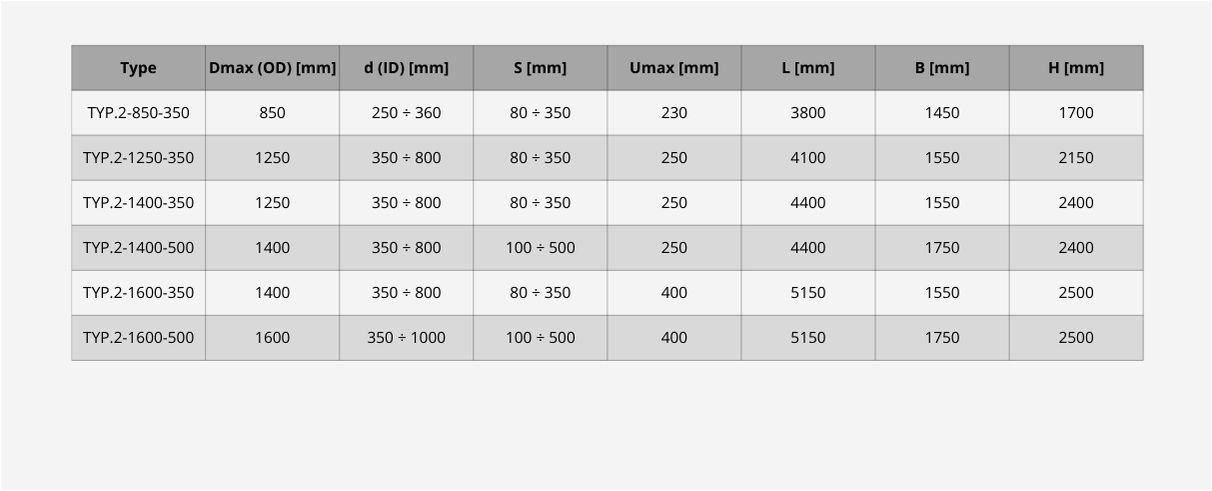

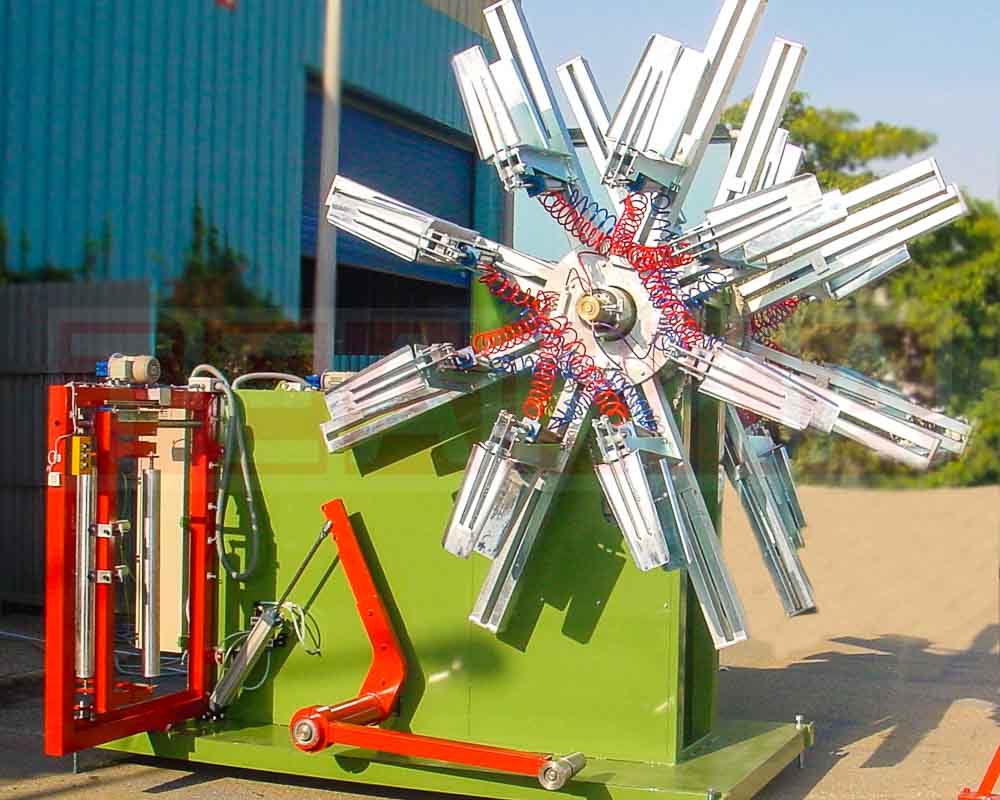

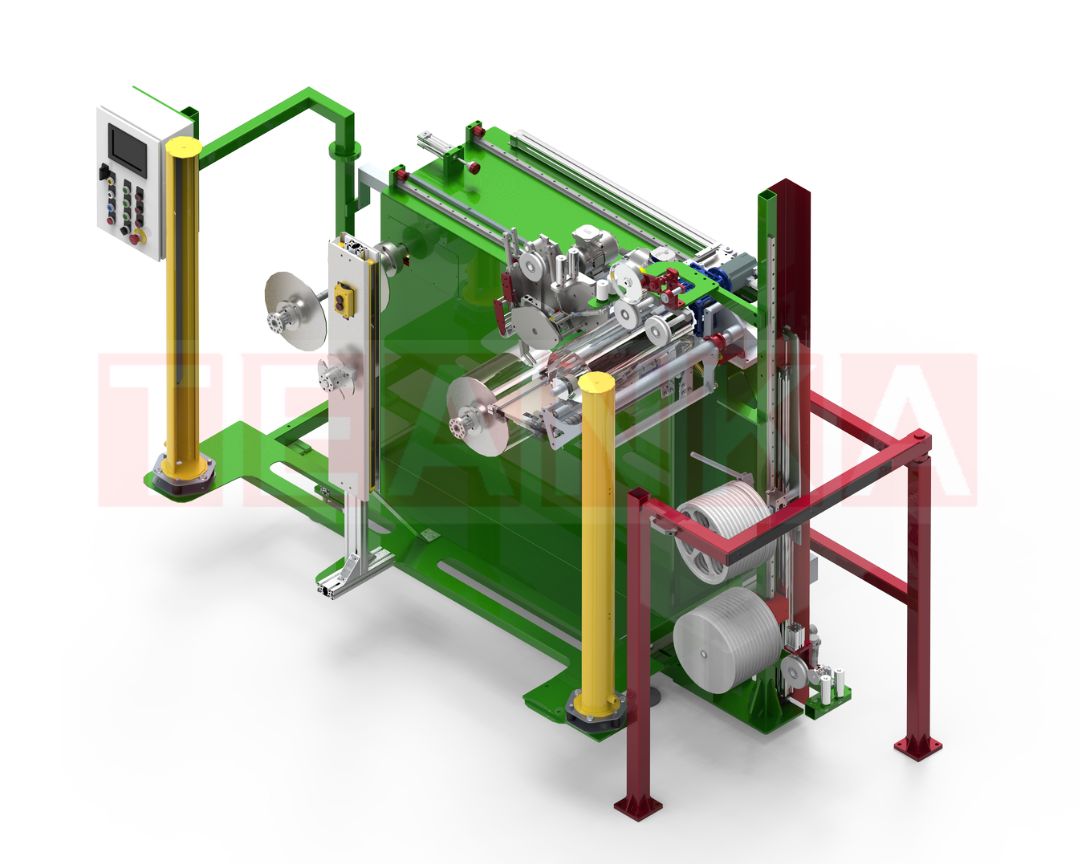

TYP-2-850/1600 | Mid-sized Double Winding Stations

TYP-2-850/1600 series are medium- sized double winding stations, with a winding diameter of up to 1600mm. They are ideal for pipe production lines up to Ø 40mm.

Features

- Two (2) winding stations.

- 7” Touch Screen and Siemens PLC, with Industry 4.0 standards.

- Semi-automatic winding function.

- Shrinking the navel wrap for easy extraction of the coil.

- Ability to communicate with the cutting machine to carry out stopping procedures.

- Ability of simultaneous operation of both stations, winding 2 different tubes.

- Large coil width for long rolls.

Optional equipment

- Automatic cutting by measuring the pipe length in the station or by command from the production line or the printer.

- Automatic coil tying system.

- Inserted wings to change the winding curvature for better results in thin pipes and in different diameters.

- Holding arm for optimal winding quality and easy tying by the operator.

- Wheels for easy movement within the production area.

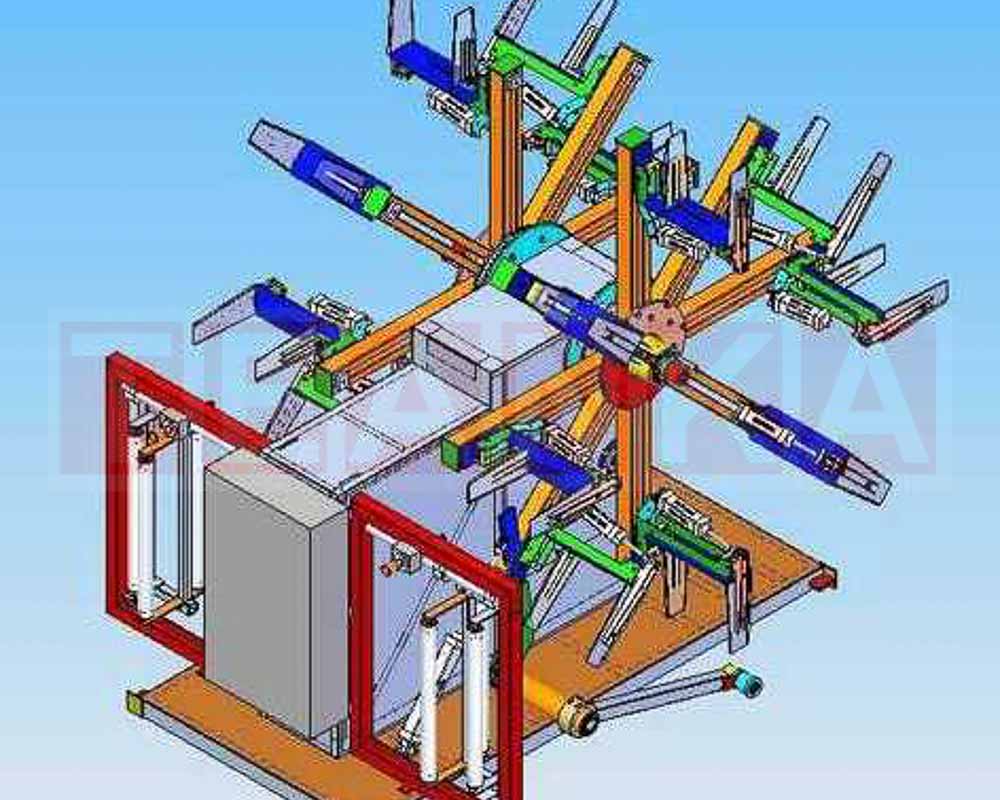

Custom Made Winding Stations and Systems

TEANKA designs and manufactures CUSTOM MADE Winding Stations and Systems, according to the customer's needs..

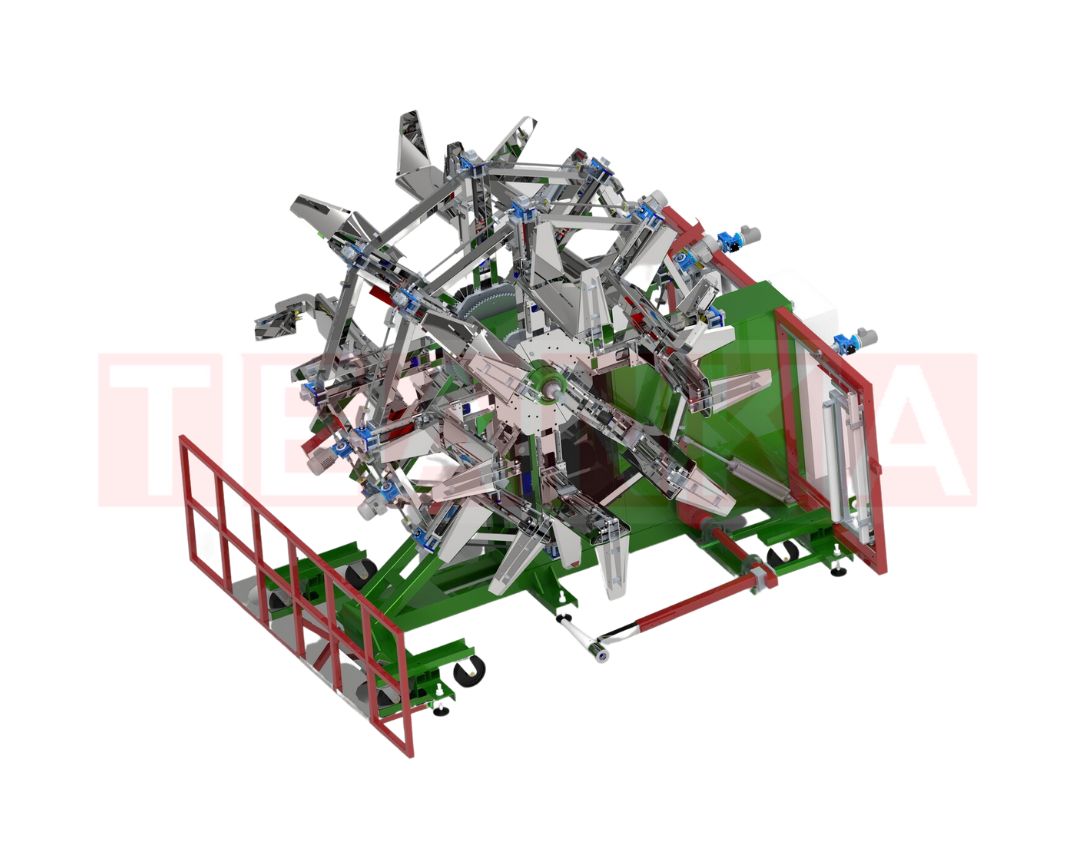

Specially designed Winding Stations

- With one or two winding stations.

- For winding on metal or wooden spools.

- With automatic winding function.

- With automatic coil change.

- Special design for sensitive materials.

- Winding stations with winding diameter greater than 3500mm.

- For mileage coils.

Double semi-automatic station

- For pipes from Ø 3mm to Ø 10 mm.

- Maximum winding speed: 180 m/min.

- Automatic coating with stretch film.

- With the ability of placing paper spools.

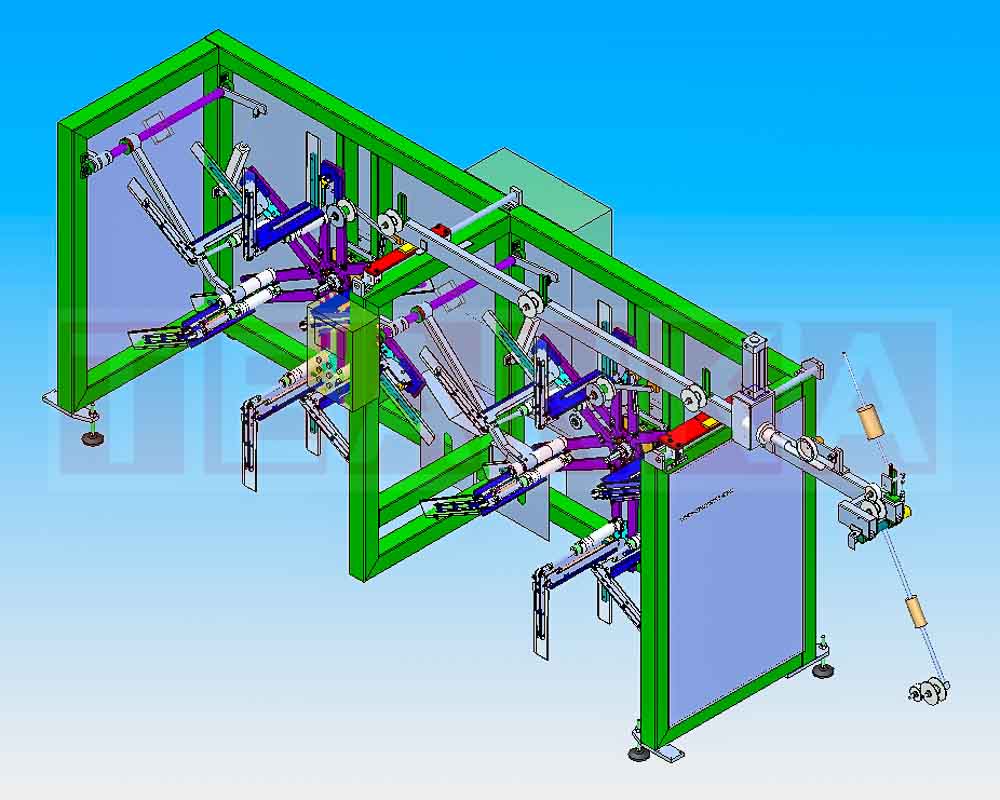

Automatic winding station for flat irrigation pipe

- For pipe from Ø 16mm to Ø 22mm.

- Maximum winding speed: 350 m/min.

- Winding length up to 3000m.

- Automatic changes.

- Small machine width (1450mm).

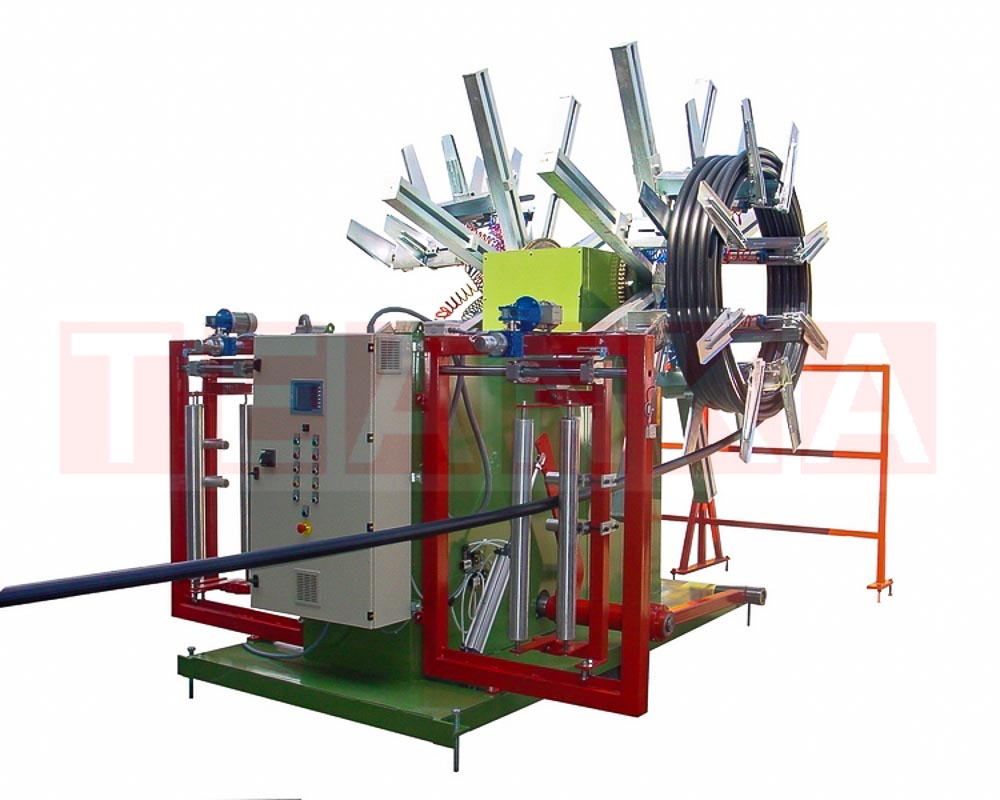

Winding station for long pipe lengths

- For pipes from Ø 16mm to Ø 32mm.

- Maximum winding speed: 60 m/min.

- Winding length up to 7000m.

- Coil winding.

- With one or two winding stations.

More Winding Stations and Models

Press to zoom in

Coiler TYP2/3500X

Coiler with plastic strap

Coiler with strap

Artemis automatic coiler

Tailored jumpo coiler

Winding Station TYP2/2200

Coiler TYP1/2400X

Available Downloads

Press to download this